We offer a full array of key services in our

Services

Each day we work to advance innovative manufacturing

technologies that promise cures, making cell and gene

therapies more accessible to everyone.

Process Development

We offer an end-to-end solution for viral vector manufacturing, from cell line to drug product, emphasizing process robustness and quality. Our platform approach minimizes new development, allowing for the rapid creation of toxicology batches shortly after contract signing. With Quality by Design (QbD) principles, we transition directly to GMP production, saving you time and resources for study design.

cGMP Manufacturing

Our commitment to quick clinic delivery and accurate execution is fundamental to our approach. With an integrated supply chain and standardized documentation strategies, we significantly reduce GMP readiness timelines and maintain a sharp focus on the CMC specifics of your program.

Analytical Development

Our analytical services are focused on viral vector product release, emphasizing biological assays crucial for quality approval. Our team is equipped to handle everything from assay transfer to qualification and validation, aiming to effectively bring your ideas to life.

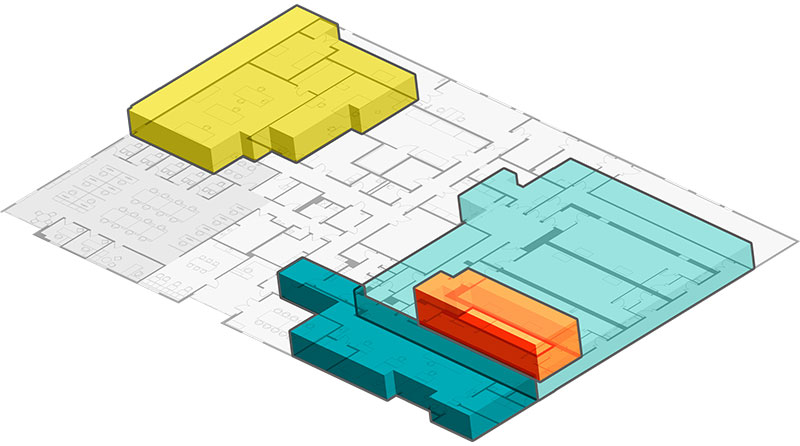

Explore the facility

Facility details

22,434 sq ft

BSL2- ISO7/ISO8

5 dedicated, cGMP suites

Dedicated Process Development

& Toxicology (GLP)

Dedicated RUO Vector Core

On-site Warehouse

& Cold-Chain Storage

24/7 environmental monitoring of

production suites and cold storage

Integrated Analytical Suite

Quality is at the core of what we do

Our comprehensive quality assurance program means that

viral vector products are manufactured and tested in full

compliance with cGMP regulations and adhere to FDA Good

Manufacturing Practice (GMP) requirements.

With more than 40 years of quality assurance program

management, our team has adopted a “right first time”

culture, dedicated to proactive quality program

management to ensure the quality of your product.